Cylindrical cans with insulation are also used in certain applications. The housing includes a breakaway barrier between the main cold box and the external housing to.

Conceptual Design Of The Cryogenic Distribution Line And Valve Box For Download Scientific Diagram

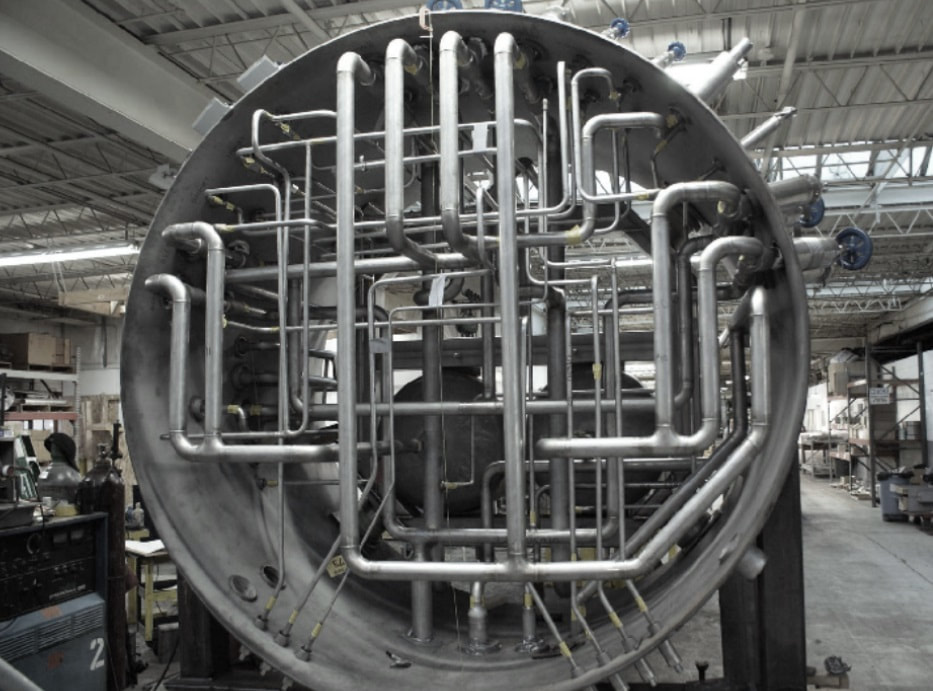

Example of Complete Package Design.

. We have enhanced the capability to make oversized cold-boxes each of which can be loaded as a single piece onto a barge at the Hangzhou manufacturing. The distillation unit includes at least one cryogenic distilling column and at least one heat exchanger arranged in a chamber with a double casing in which the intermediate partition contains a solid insulator. One 4 K part and another 20 K part.

There are many different design concepts for low temperature and cryogenic storage vessels. This regime occurs for gas densities where the mean free path is less than the wall spacing. 4 Flow chart of Air separation unit The compressed air is passed through heat exchanger which.

Cryogenic Valve Model C2041-C21-1194. Packaged units also known as coldboxes are utilised in a wide range of applications for the treatment of cryogenic fluids and gases including air separation plants gas separation and liquefaction plants chemical and petrochemical plants. Reduces the temperatures of the air around -140C.

A cold box of the current invention includes a housing partially extending out of the cold box jacket wherein equipment that may need to be accessed can be located. 34 Cold box and cylindrical enclosure A cold box is an enclosure containing insulation that separates a cryogenic process from the surrounding environment. We deliver a range of coldboxes in sizes of up to 5 m by 7 m and up to 40 m long.

The cold box in an air separation unit is a highly engineered large rectangular box enclosing the major cryogenic equipment. This disclosure discusses providing safer and more accessible insulating cold boxes for cryogenic equipment. 5 Cold Box Cuff Globe Valve Pneumatic Actuated Operation.

So the chamber can be thought of two chambers. In order to reach cryogenic temperatures a vacuum chamber Dewar containing the receiver is evacuated to a very high vacuum and a closed-cycle refrigerator is used to remove the heat. The cold box containing all cold equipment is designed considering strength and thermal aspects.

Capacity upto 2 kW at 45 K. Component layout inside the chamber is decided to maintain a temperature gradient through the length of the chamber. Plant comes complete with coldbox turbine duct and control system based on customer.

The cold box wall is made up of steel panels that are welded onto the cold box frame. The physical character of expanded perlite lends itself to a variety of special purposes including use in insulating cryogenic and low temperature storage tanks in shipping containers cold boxes test chambers and in food processing. Cryogenic processes require insulation to reduce heat transfer from the surrounding.

Packaged or bulk perlite may be used to insulate smaller vessels by pouring or through pneumatic pumping by our installation crew. Our engineers can assist in detailed engineering for instance converting US based design to European standards. Design and analytic services for cryogenic heat exchangers pre-launch LOX and H2 densifiers MLI systems H2 liquefiers storage and transport dewars mixed gas coolers and LNG systems.

Structural analysis and seismic design will be performed at basic design of steel structure frame. Staff is comprised of highly skilled and experienced engineers and designers who are career-long experts in deep cryogenic system design. Capacity upto 2 kW at 45 K.

The cooling of air is allowed by passing the cold. CryoCore can provide cold box technology for a wide variety of processes. Coreworks Cryogenics partner has built over 70 unique configurations in a variety of sizes with more than 180 cold boxes and assemblies built.

Irrespective of the customer planning to build his own ASU or revamp an existing ASU. Energy business line is specialized in the design manufacture installation and maintenance of brazed heat exchangers cold boxes cores-in-drums and. Cryo Technologies vacuum cold box engineering design and fabrication expertise affords us the ability to offer our customers helium and hydrogen liquefiers of unparalleled performance and quality.

A Chart BAHX is a highly efficient all brazed and welded compact heat exchange device that offers distinct advantages versus other heat exchanger types. It also provides structural support for the equipment. They are designed in accordance with the worlds pressure.

Thus the cryogenic system is a crucial element governing a receivers performance. A rectangular cold box consists of a steel frame with panels of sheet metal. For a detailed explanation of perlite expansion see info sheet.

Reference of cold boxes for cryogenic industry. However most are of double wall construction with the annulus filled with expanded perlite. Cryogenic Processes LNG Gas NGL Recovery Air Separation.

The cryogenic equipment is enclosed in an insulated enclosure termed a cold box. Fives is a pioneer with more than 60 years of industry-leading expertise in cold box design production installation and. The unit can be on board offshore floating terminals and.

Mineral wool was used for insulation prior to the late 1940s. To a cryogenic system At pressures near 1 Atm the heat transfer is by natural convection At lower pressure convection is reduced but gas conduction still can transfer considerable heat k T. Astronomy receivers are generally operated at cryogenic temperatures.

Vessel Post filter Cold box Cold box Heat exchangers Expansion turbines Inlet and out let manifolds A column consisting of aluminium rays. Chart Industries pioneered the use of BAHX for cryogenic gas processing in the 1950s and weve produced over 13000 units since. 35 Cryogenic Cryogenic processes operate at temperatures below approximately -90C -130F from EIGA Doc 146 10.

Cryonorm can also offer standardized Nitrogen plant for cryogenic purity GAN 1000 Nm 3 hr production and up to 10 LIN production. Some suppliers use a round silo design in which the equipment is primarily supported from the cold box foundation. SASPG can design and supply a cold-box based on specified gas production requirements.

However the term cold box is sometimes used to refer to all enclosures regardless of cross section shape.

Custom Cryogenic Distribution Boxes And Cold Boxes Meyer Tool Mfg

Cold Box Sumitomo Precision Products Co Ltd

Fives Energy Cryogenics Cold Boxes Fives Group

Cryogenic Cold Box Cryocore Sme Process Solution Llc

Cold Box Sumitomo Precision Products Co Ltd

Main Components Of A Cryogenic Valve For Cold Helium Installations Download Scientific Diagram

0 comments

Post a Comment